OPEN THE DOOR TO A NEW KIND OF DÉCOR

New Door Modern Line front doors not only perform their maximum security and insulation duties as best as possible, but are also a preview of the style and design expressed by your whole house.

To best satisfy even the most demanding customer’s needs, New Door provides a wide range of different styles: from simple, conventional lines to more intricate and visually striking ones, from a clean, minimalist design up to a mix of different materials (e.g. frosted stainless steel).

Specifically, New Door also provides flash-mount processing to create a unique, luxury Modern Line door, improving its design with simple, consistent lines.

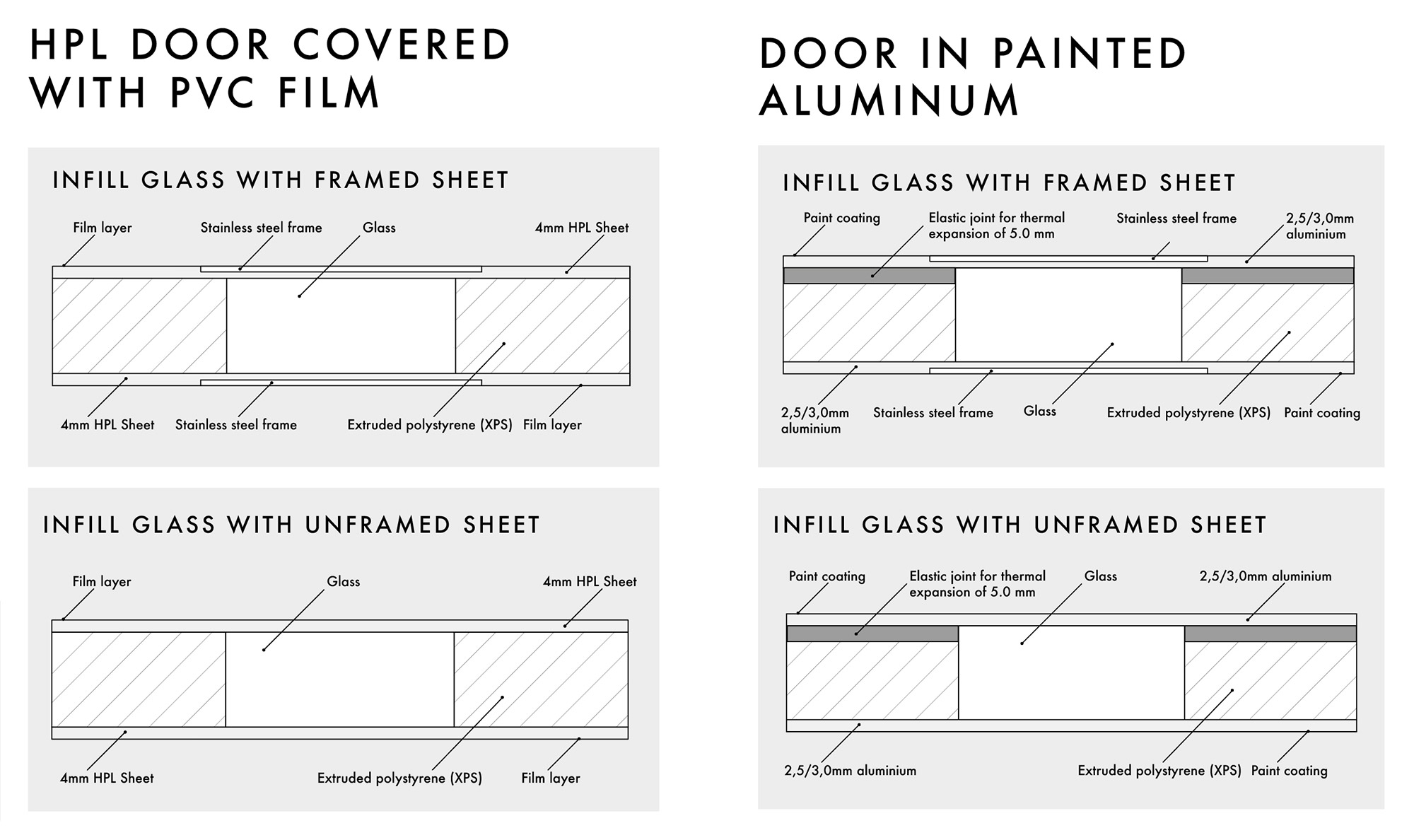

The different effect between the two processing methods for front door panels is shown here:

PROCESSING TECHNIQUES AND DETAILS

Attention to detail

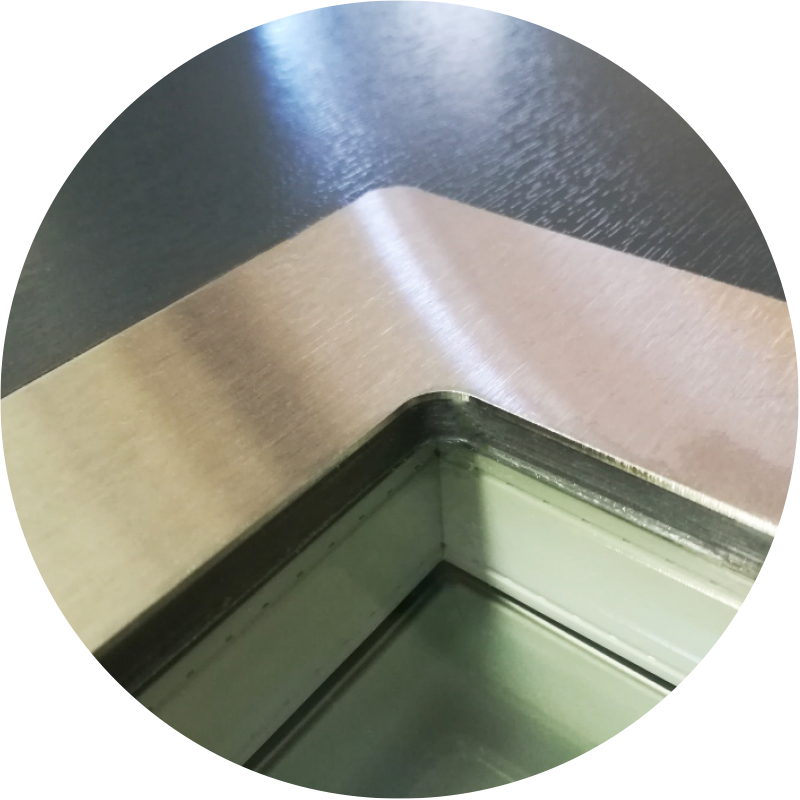

One of our values consists in striving for perfection and paying attention down to the smallest detail.

Finishes

When we coat even the most impervious corners in PVC film (upon request), we pay attention to details as well.

Suitable for security doors

New Door recommends 6mm-thick HPL sheet panels.

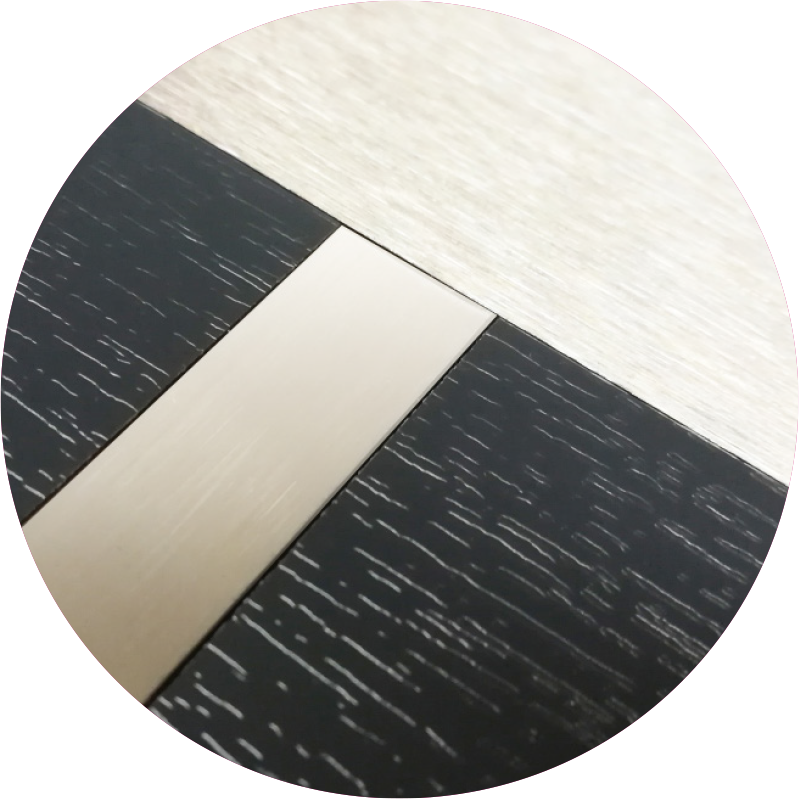

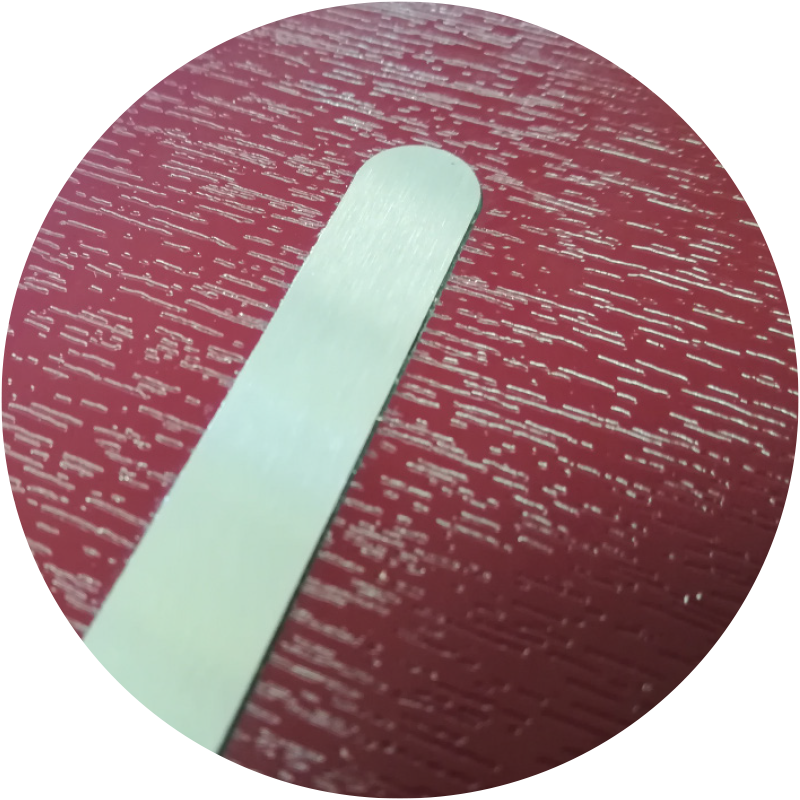

Elegant finishing

Matching the materials a front door panel is made of in an elegant way was the first goal we reached.

Flush inserts

Stainless steel flush inserts add an elegant touch to the panel.

Rounded inserts

Stainless steel rounded inserts further accentuate the smoothness and harmony of lines.

TREATMENT PROCESS

Modern Line front door panels are self-supporting, structural sandwich panels comprising a core made of extruded polystyrene (XPS) — or other materials upon request — coated with 4mm-thick HPL sheets. These sheets are contoured by pantograph to allow for the insertion of profiles, glazed panels, etc., and then coated with wood-look or plain colour outdoor-grade PVC film (provided by our manufacturers RENOLIT® and HORNSCHUCH®) by using proper adhesives. Any inserted profiles are properly glued.

GLAZING

Any glazed panel can be placed everywhere, depending on the customer’s needs: therefore, we can offer a wide range of glazed models.

APPLICATIONS

These panels are primarily used to manufacture front doors and security door panels.

PROPERTIES

Thermal insulation.

Acoustic insulation.

Great dimensional stability to temperature changes.

Impact resistance.

Coated panels are resistant to UV rays and other weather conditions (see film manufacturers’ certifications).

SIZE

Standard size max: 990 x 2240 mm

Non-standard size: 1290 x 3040 mm

Cut-to-size service included.

XPS BOARD DENSITY

35 kg/m³

HYGROSCOPIC PROPERTIES

The materials used are not hygroscopic, therefore this product is not subject to imbibition by capillary action.

TOTAL THICKNESS

Front door panel: 28, 32, 36, 40, 44, 48 mm

Security door panel: 6 mm

Other thicknesses available upon request (± 1mm tolerance)

RESISTANCE TO CHEMICALS

The product can withstand all weather conditions as well as ordinary (non-abrasive nor corrosive) household cleaners. The product does not withstand organic solvents (e.g. thinners, solvents, adhesives and so on,) either alone or in mixtures, as specified within the certifications provided by the coating manufacturer.

MAINTENANCE

The product does not require regular maintenance: typically, cleaning it with a standard household detergent (except abrasive and corrosive ones) is enough. You can ask the film manufacturers for a list of recommended cleaning products.